GEOTHERMAL

RENEWABLE HEATING & COOLING SOLUTIONS

Our geothermal solutions help developers eliminate the use of fossil fuels to heat and cool buildings, reducing carbon emissions and helping to achieve sustainability goals and mandates.

WHY GEOTHERMAL?

Up to 40% Federal Investment Tax Credit

The Inflation Reduction Act (IRA) includes up to a 40% Federal Investment Tax Credit (ITC) on both the geothermal ground loop system and the interior mechanical equipment. This credit is not available for air source heat pumps. Not for Profit 501(c) organizations are now eligible to receive cash in lieu of the tax credit under the ‘Direct Pay’ provision.

It can significantly lower operational expenses

Due to the efficiency improvements geothermal energy systems provide, HVAC operating costs can be lowered by 30%-40%. Maintenance costs can also be reduced by up to 75%.

It is the most efficient HVAC solution with the lowest carbon footprint

Geothermal eliminates the use of fossil fuels in the heating and cooling of buildings. In cold climates, it is 3-4x more efficient than gas-fired systems. These two attributes greatly reduce carbon emissions.

Available State and Utility Incentives

Many states and local utility companies also offer significant incentives for ground source heat pump systems.

Carbon Neutral Ready

Local and federal mandates are requiring buildings to reduce their carbon emissions. Geothermal is a great solution to help meet sustainability mandates and goals.

Long Operational Life

The operational life for a geothermal ground loop exceeds 100 years and the heat pump is 25 years. This makes a geothermal system the best option for a long-term solution.

CHECK OUT OUR LATEST LANDMARK GEO PROJECT

IN THE HEART OF NEW YORK CITY

WHY BRIGHTCORE?

OUR TECHNOLOGY.

Cutting-edge technology:

Brightcore utilizes industry-leading technology in our development and construction process, allowing us to uniquely offer both conventional and confined space drilling. We also provide long-term preventative maintenance and monitoring utilizing our own proprietary software.

Smaller footprint:

Utilizing proprietary drilling technology, boreholes are capable of being drilled at inclined angles, with a much smaller footprint at the top and larger footprint at the bottom. Because it uses water for drilling instead of compressed air, it allows for drilling in bedrock.

Fleet Diversity:

At Brightcore, we have both truck mounted drill rigs as well as custom mini-rigs in our fleet. That allows the capability to install a geothermal ground loop in new construction or open-space environments, as well as in existing buildings and areas with limited access.

Having multiple rigs enables us to reduce project lead time by operating several rigs simultaneously.

We have access to a fleet of drill rigs and can run several rigs simultaneously to reduce project lead time.

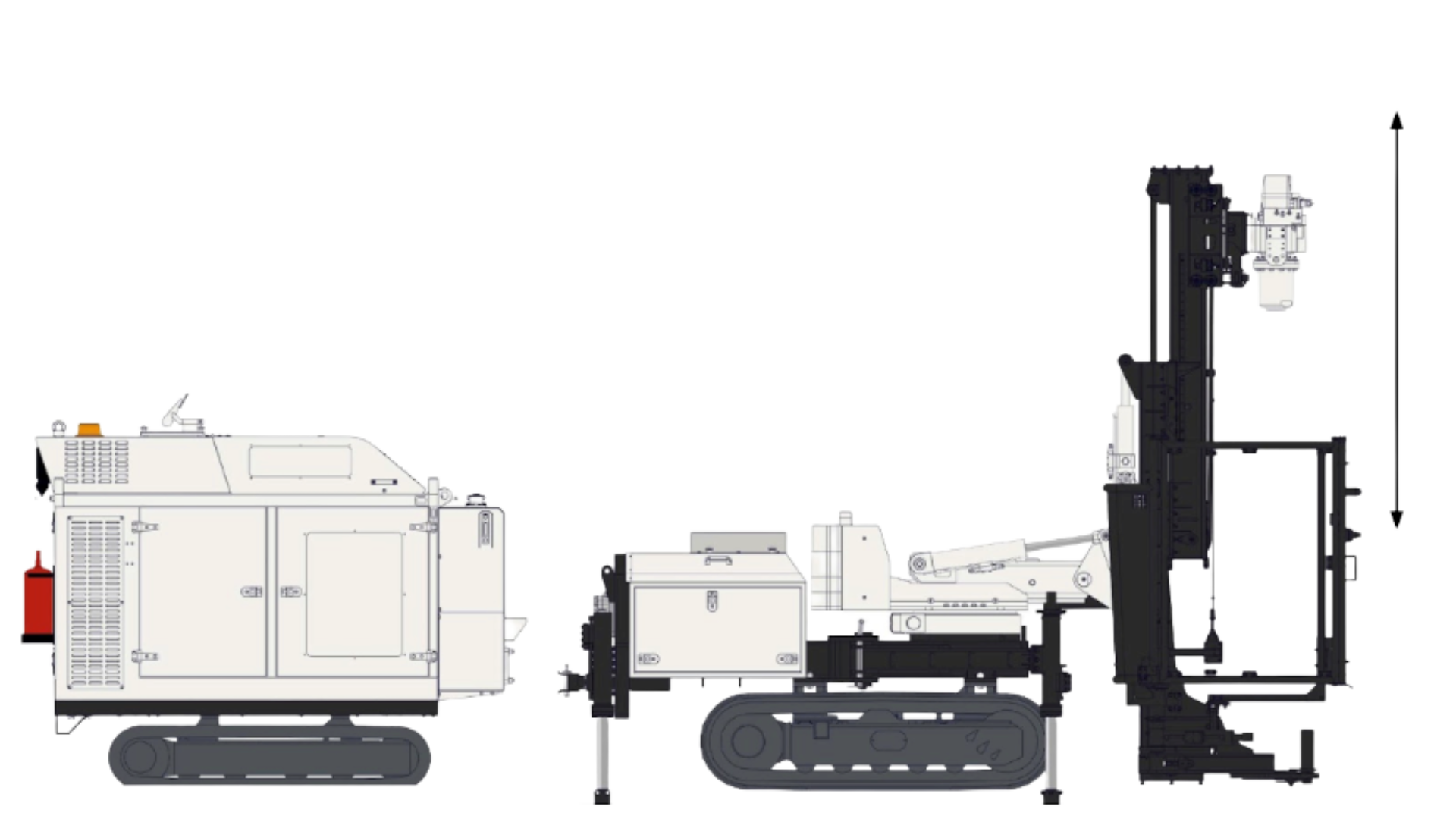

BRIGHTCORE CUSTOM MINI RIG

Great for installations in difficult terrain and low clearance spaces

Not available in the U.S. market - until now!

- Rig width: 3.4 ft

- Rig Length: 10 ft

- Height (rig derrick up): 9.5 ft

- Power pack width: 5.3 ft

- Power pack length: 7.5ft

- Power pack height: 5.1ft

CONVENTIONAL DRILL EQUIPMENT

Great for installations

in large open areas

in certain geological

settings.

- Height (rig derrick up): 30-33 ft

- Length of 6x4 truck: 29.5 ft

- Width of 6x4 truck: 8.4 ft

- Height of 6x4 truck: 11.2 ft

WHY BRIGHTCORE?

OUR UNIQUE GEOTHERMAL BUSINESS MODEL:

Turnkey Model

Project Feasibility, Engineering, Drilling, Financing, Incentive Optimization, O&M

Reduces Risk, Streamlines Process, Lowers Cost, Shortens Schedule

Technical Expertise

Geothermal Assessments, Design, Policy, Incentives

Optimizes Project Design, Maximizes Savings

In-House Drilling

Company-Owned Rigs, Licensed Master Drillers, Fully Staffed Drill Teams

Optimizes Results and Accelerates Schedule

Innovation

Proprietary Water Hammer, Custom Mini-Rig, Incline Drilling, Electric Drilling, High-Performance Heat Exchangers, Thermal Demand Response

Enables Installation in Space-Constrained Areas, Optimizes Performance

Energy as a Service

In-House Capital to Fund 100% of Project Cost

Eliminates Upfront Investment

Financial Strength

Backed by Leading Sustainability Investor, Strong Bonding / Insurance Program

Eliminates Risk

Local Presence

On-the-Ground Resources, Drilling Yards in NY & MA, Northeast Licensed Drillers, Strong Relationships with Local Utilities and State Energy Agencies

Optimizes Execution

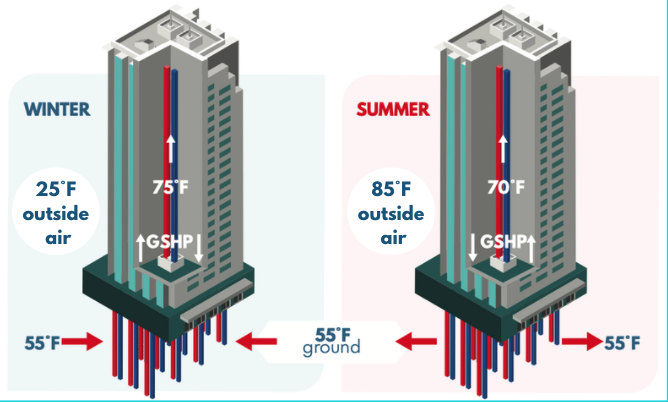

BASICS OF HOW GEOTHERMAL HVAC WORKS

Heat pumps move energy to efficiently heat or cool a space

In the winter the heat pump boosts the relatively warm ground temperature to heat the building.

In the summertime, the geothermal system rejects heat to the cool ground and uses the cool ground temperatures to operate at extremely high efficiencies.

For every unit of electricity used 4 units of energy comes from the ground in the form of renewable heat. This makes Geothermal systems up to 50% more efficient than conventional air conditioning.

-

In the winter the ground is a heat-source

-

In the summer the ground is a heat-sink

Closed loop geothermal heat exchanger

GSHP= Ground Source Heat Pump

GEOTHERMAL MYTHS DEBUNKED

Myth: Geothermal systems don’t work in urban areas

There are a few geothermal systems in urban areas, especially New York City! Closed-loop ground source systems are typical installations for urban environments and are good considerations for new construction.

Myth: It’s not possible to drill in bedrock

Bedrock actually has great thermal conductivity properties and certain drilling equipment is capable of drilling in bedrock to install ground loops.

Myth: Geothermal systems are hard to operate and maintain

Once the ground loops are installed and sealed, there is no maintenance involved. Operations are related to water source heat pumps and piping, but generally do not require further specialized knowledge. Geothermal systems will offer less O&M and have longer useful life than other systems since all equipment is underground and inside the buildings, protecting the system components to everyday and extreme weather events.

Myth: Geothermal systems cannot be installed inside existing buildings

Brightcore’s fleet of rigs includes a custom mini rig, which is specifically designed for drilling indoors. It is smaller than conventional equipment with 10 feet head clearance and 9 feet long, allowing it to fit in small spaces with low overhead clearance, while minimizing the risk of damaging surrounding buildings or structures.

Myth: Does a geothermal heating & cooling system circulate refrigerants and/or lava?

Closed loop geothermal systems circulate a mixture of water and anti-freeze in the ground loops to the heat pumps. Heat pumps use refrigerants for heat conversion, but geothermal systems minimize and centralize the refrigerants to the heat pump itself. The refrigerant isolated in one geothermal system component makes it simple to dispose of and replace at the end of the heat pump life (up to 25 years!)

Myth: Geothermal drilling can deviate significantly from the planned drill pathway

While it is true that conventional air-down-the-hole (ADTH) drilling techniques typically deviate from their expected drill path by up to 10%, Brightcore’s proprietary water-down-the-hole (WDTH) drill rig only deviates from its drill path by about 1%. In a densely populated area like New York city, this higher degree of precision allows for more precise drilling in ‘close quarters’ near critical underground infrastructure like NYC water tunnels as well as in and around landmarked buildings.

Myth: Ground loops have to be replaced

Manufacturer warranties range from 50 to 65 years, but the ground loops themselves can last more than 100 years with the durable HDPE piping and limited exposure to weathering.

Myth: Geothermal systems cannot be integrated with air-source heat pumps

Combining ground source and air source heat pumps can produce the most efficient solution by leveraging each technologies’ efficiencies. For heating and cooling in shoulder seasons with milder temperatures, ASHP can operate at its highest efficiencies. On the other hand, geothermal can supply a majority of demand during peak hours and temperatures with the lowest electricity use. Together, each system can work together to meet building demands in the most efficient way.

Myth: Geothermal systems cannot be installed in bedrock

Although drilling in bedrock with traditional equipment, such as an air hammer and mud rotary, is not impossible, it can be challenging and messy. This would be applicable to sites that have lots of space and wouldn’t interrupt surroundings. On the other hand, the Water Down Hole drill is specialized to drill in bedrock without major debris or disruption. For this reason, the five boroughs, and Manhattan especially, are ideal drilling locations for ground source heat pump installations.

Myth: NYC is bad for geothermal heating & cooling systems

NYC’s iconic skyline wouldn’t be possible without bedrock as its foundation. Bedrock can also become the pillar for renewable heating and cooling by using a specialized water-down-the-hole (WDTH) drilling technology capable of accurately drilling in rock. The combination of types of bedrock and its ideal thermal qualities, NYC is a great candidate for ground source heat pumps.

Myth: Geothermal heating & cooling systems circulate lava through a building

For ground source heat pumps to provide enough heating and cooling for large commercial or multifamily buildings, it’s common to drill 500 to 800 feet. However, this drilling occurs in the crust of the Earth and not the mantel where magma circulates 225 miles below!

Instead, closed loop HPDE pipes circulate water and anti-freeze in the ground to transfer heat for building geothermal heating and cooling applications.

Myth: The drilling process causes earthquakes

Drilling operations are not large enough to cause geological impacts as intense as earthquakes. Geothermal installations should be considerate of any existing sensitive geologic conditions such as existing fault lines, but are not able to create extensive fractures.

Myth: Geothermal systems require a lot of outdoor space

Conventional drilling techniques require at least 20’ of spacing between boreholes, if not more, Brightcore’s UrbanGeo inclined boreholes only require ~ 5’ between each borehole.